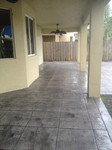

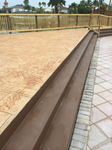

Stamped concrete is a decorative technique

that involves imprinting patterns or textures onto freshly poured concrete to mimic the look of other materials like stone, brick, or tile. Here is a general overview of the stamp concrete

process:

1. Site Preparation: Prepare the area where

the concrete will be poured by clearing any debris, leveling the ground, and installing appropriate forms or edge restraints to contain the concrete.

2. Pouring the Concrete: Pour the concrete

mixture into the prepared area, ensuring it is evenly spread and at the desired thickness. Use a screed board or bull float to level and smooth the surface.

3. Coloring the Concrete: Apply a concrete

colorant or integral color to the concrete mixture before pouring. This will give the concrete its base color and enhance the appearance of the stamped pattern.

4. Stamping the Concrete: Once the concrete

has partially cured and is firm enough to hold the weight of the stamps, begin the stamping process. Press the stamps onto the surface of the concrete, starting from one corner and working your way

across. Use a combination of different stamp patterns to create the desired look.

5. Detailing and Texture: Use smaller hand

tools or specialized stamping tools to add additional details and textures to the stamped concrete. This can include adding grout lines, texture mats, or creating realistic stone or brick

patterns.

6. Curing and Finishing: After the concrete

is fully stamped, allow it to cure for the recommended time, typically around 24 to 48 hours. During this time, cover the concrete with plastic or a curing compound to prevent moisture loss. Once

fully cured, wash off any release agents and debris from the surface and apply a concrete sealer to protect and enhance the appearance of the stamped concrete.

It is important to note that stamping

concrete requires skill and experience to achieve desired results. It is recommended to hire a professional concrete contractor who specializes in stamped concrete to ensure a high-quality and

long-lasting finished product.